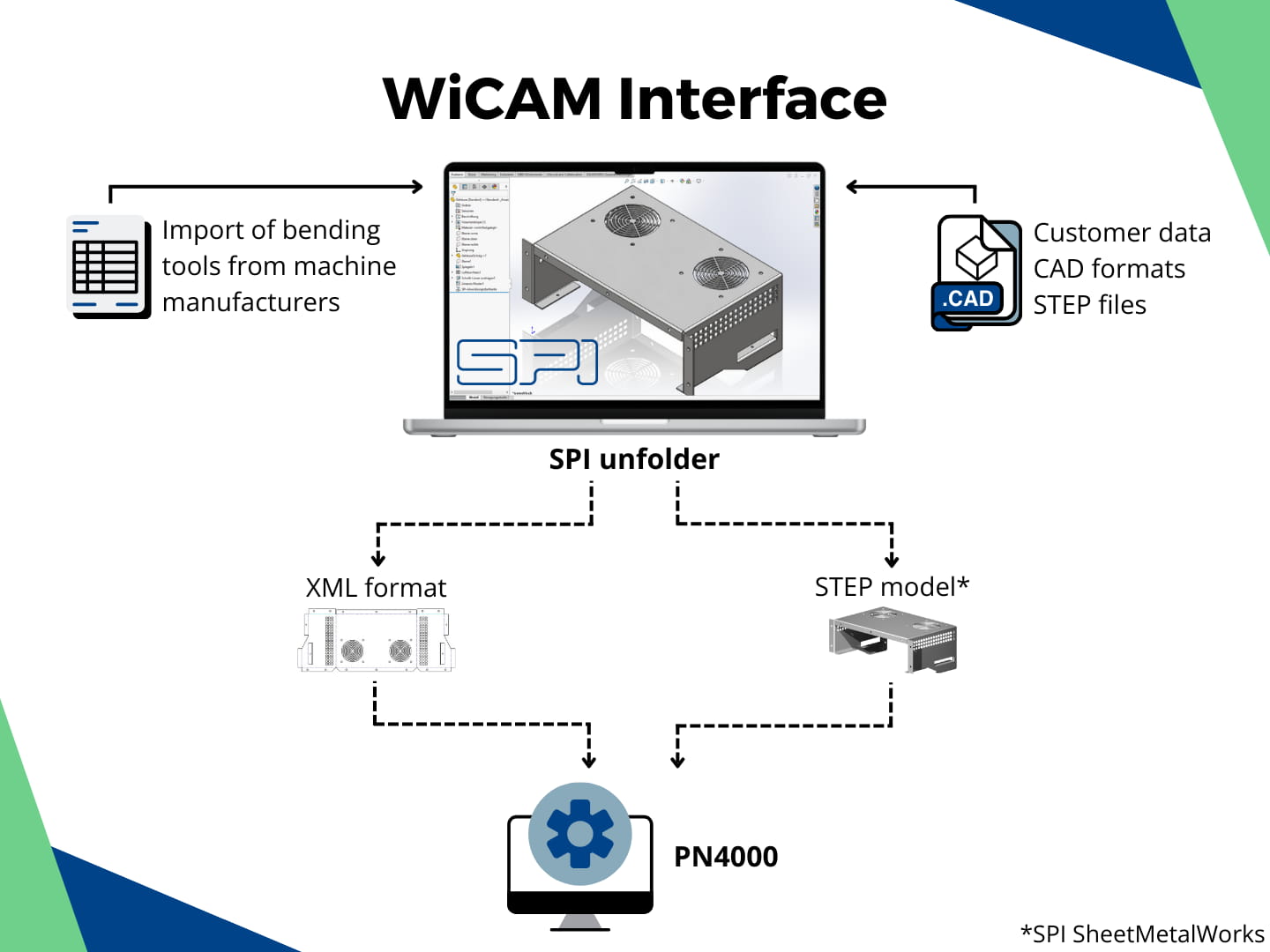

WiCAM Interface

Data processing in the sheet metal process chain. Output formats for PN4000.

Calculation base and output principle

The calculation for the output is based on the data maintained in the material and tool manager, the SPI Data Editor. The SPI add-in generates the flat pattern and provides appropriate output formats with all production-relevant data.

PN4000

SPI creates a WiCAM XML file with specific content that can be used directly by WiCAM’s PN4000 for NC code generation and control of various machines. PN4000 is the CAD/CAM Nesting system for ERP/PPS controlled programming of CNC cutting, punching, shearing, milling, and combined machines. The diverse modules and interfaces enable flexible contract manufacturing up to a fully automated industrial process chain.

In addition, SPI can provide a manufacturing-ready STEP file with the specific process information (prerequisite: SheetMetalWorks with Solidworks).