Designing for manufacturing reduces errors and saves time for everyone involved. One of the most effective ways of linking CAD and fabrication is by ensuring that your flat patterns contain all the necessary manufacturing information.

This is easily achieved with the help of SPI Sheet Metal Solutions!

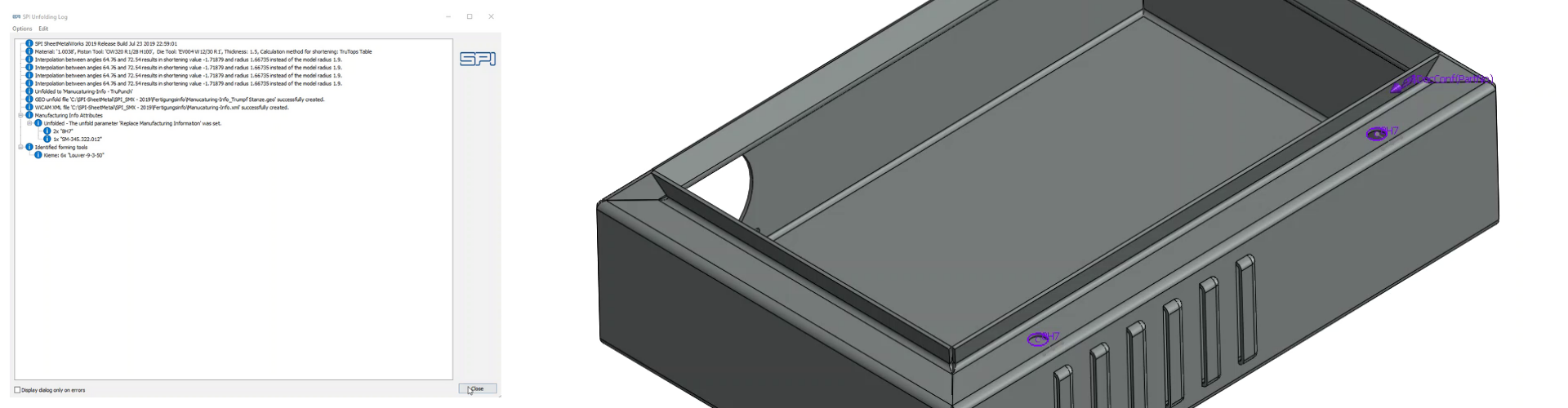

Both SPI SheetMetalWorks and SPI SheetMetal Inventor allow you to add manufacturing information to your model so that it is always output during unfolding. The information is displayed according to your chosen output format, e.g., as bend lines, tool IDs and other attributes for GEO files, or as layers and colors for DXF files.

Click play to learn more!

Adding manufacturing Information with SPI SheetMetal Solutions

Videos in the Series

Learning tool recognition

A super useful function for those who frequently work with imported sheet metal parts.

Data output formats

Simultaneously generate several different output formats during unfolding, e.g., DXF, GEO, XML.

Unfolding assemblies

Assign material data and other settings to all sheet metal parts and unfold them with a single click.

Bend reliefs

Ensure that your sheet metal part has bend reliefs suited for material thickness and bend radius.

Non-native data

Attach material information, adjust accuracy settings, insert bend marks, and more without modifying the imported model.

Manufacturing information

Effectively link CAD and fabrication by making sure that your flat pattern contains the necessary manufacturing information.